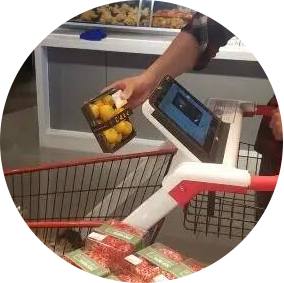

Unmanned Retailumables Management

Through automatic recognition technology, products can be quickly and automatically identified in batches, settled automatically, and the shopping experience of consumers can be improved.

Shopping Cart Guide

Monitor and guide consumer action routes, collect information on product sales, and provide recommendations for product placement, channel guidance, and marketing activities.

Product Behavior Analysis

Collect consumer behavior data in the store, combine it with sales information to make scientific analysis, and provide decision-making basis for product procurement, placement, promotion and other activities.

Receipt Of Goods

Automatically verify receipt documents and quickly classify them for easy storage.

Storage and Replenishment

Ensure that the arriving goods are placed in the correct location for quick picking, while conducting inventory and turnover analysis to achieve scientific replenishment.

Inventory and Material Management

Real time status and location visualization of all goods to improve subsequent production and inventory efficiency.

Goods Picking

Using various indicator methods such as lighting and electronic paper for picking to improve accuracy and efficiency.

Packaging and Shipping

Assisted by scanning codes, RFID, image recognition, and other forms, while improving manual operation efficiency.

Cross Warehouse Delivery

Ensure the accuracy of logistics and pallet loading, and improve delivery efficiency.

On Site Transportation and Distribution

Automatically identify cargo information, perform multi link verification, optimize delivery processes, delivery routes, and transportation resources. Simultaneously achieve safety management through basic information of vehicles and personnel

Reverse Logistics

Reverse supply chain full process tracking to obtain real-time material information, allocate inventory reasonably, and promote processing flow.

Cold Chain Management

Realize stable operation, fast operation, cost reduction and efficiency improvement under complex working conditions, and shorten the stay time of personnel in the cold storage.

Vehicle Management

By tracking the real-time location and status of vehicles, we can maximize the utilization of vehicle resources, reduce safety accidents, and achieve event tracing.

Warehouse Management

By using intelligent IoT hardware, automatic inventory counting, picking guidance, outbound registration, and replenishment instructions can be achieved, achieving the effects of cost reduction, efficiency improvement, and safety control.

On-Site Inspection

IoT hardware empowers the inspection process, standardizes the inspection workflow, tracks the inspection process, improves work efficiency, and avoids safety hazards.